Best Practices for Antenna Installation and Maintenance

Feb 02, 2020

The Problem

A lead engineer at BusinessCom who was reviewing a service ticket, noted a problem that crops up from time to time in tropical/equatorial countries. This was the response to the client, an experienced partner, after running diagnostics on a small commercial iDirect Broadband service:

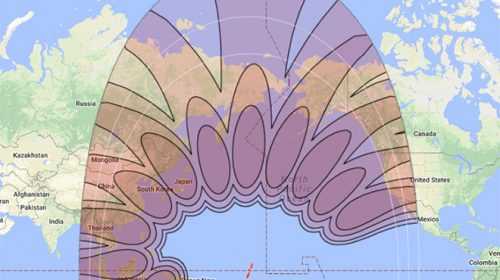

I’ve checked [SITE ID] s/n [NNNNNN] remote. Please find below its RF and traffic charts for the last 2 days. We can see traffic with bursts up to 887/332 kbps, however we can see fluctuations of Rx SNR level (sometimes there are drops even to 5.8 dB level) with current level of only 8.9 dB (please notice the minimal Rx SNR level for [SATELLITE] network at this site’s location should be 10 dB). Also, we can see packet loss (please find below ping statistics) and Tx CRC errors from site. It seems there are issues with both Tx and Rx chains on remote. Please arrange a visit of technician on site to improve antenna pointing. Please check also if Tx/Rx cables have no damages and install new cables if needed, please make sure connectors are tight, not damaged and have no corrosion inside. Please check if there is no water/humidity inside the feed.

What we find is that antenna problems often lead to service quality issues, which we will discuss in this article. The service is intended to work with a certain SNR or Signal Noise Ratio which measures the quality of the signal being received. When this number falls below a certain point the site will begin having CRC (cyclical redundancy check) errors, and this will result in slow service, or if it gets bad enough – no service. This slowdown is directly related to how the TCP/IP protocol operates.

TCP/IP Data Transport – a Brief Review

Data is transferred over the internet using the TCP/IP protocol. This protocol has built in mechanisms to ensure that data is delivered without errors. There is an acknowledgment protocol that takes place ensuring that data traffic running from the sender to the receiver is transmitted error free. If the data is not transmitted error free, then it is retransmitted by the sender, until it gets to the destination correctly. In satellite networks, this is a lengthy process because the data has to go all the way over the satellite to the remote site, about 1/3rd of a second away, and then generate an “ACK” which serves notice to the sender, that it was received correctly. This ACK must come all the way back to the sender, (another 1/3 second), before any additional data can be transmitted. Because there is so much time spent waiting for ACKs, high latency services such as satellite result in slow service for IP applications (web browsing, file transfers, etc.) over satellite. In the old days, there was little that could be done about this.

To deal with the extra delay that comes as a result of satellite latency, vendors such as iDirect (now ST Engineering iDirect), developed “TCP/IP Acceleration” techniques that allowed the transmission of IP data at full speed, over satellite links, but still guaranteed error free transmission, by buffering data until the remote site ACKnowledged it, so it could be sent again if necessary. At the remote site, the modem sends the ACK to the sender locally, so the sender can continue to transmit data, even if the remote site hasn’t acknowledged that the previous traffic was received properly. The same process occurs at the hub side of the connection in the teleport. The modem or hub holds a copy of the data being transmitted until the other site does confirm error-free reception. The mechanism used by TCP/IP to guarantee error-free transmission also affects some VPNs. A more thorough description of the IP handshake process can be found here: Understanding VPNs over Broadband Satellite

This all works great when the satellite link is error free. TCP/IP traffic can flow at full speed over the satellite link. However, when there are errors on the link because the SNR levels have dropped, this means the sending and receiving devices (remote site modem and teleport hub) must start retransmitting data that was not received error free. Once this starts happening, the “TCP/IP Acceleration” techniques are effectively disabled, and the throughput on the satellite link begins to slow. This is essentially what happens with rain fade: What is Rain Fade? Having a poorly maintained antenna is a little like having heavy rain all the time.

Antenna Issues

Poor SNR levels happen when the antenna condition is less than optimal. Poor antenna conditions can lead to poor SNR levels which reduces performance. A poorly maintained antenna will require expensive service calls which can eat into a VAR (Value Added Reseller) profit margin. We encourage our partners to sell maintenance packages to their clients along with the bandwidth. As part of this service contract an annual inspection can be performed, and the antenna can be cleaned and properly weatherproofed. A moldy, dirty antenna will not receive a clean signal, and it should be washed with care.

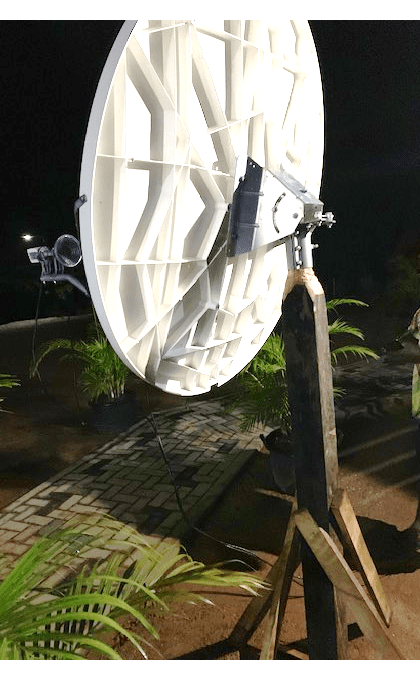

Another issue is flimsy or poorly constructed mounts – usually customized rather than ordered from a reliable vendor. These antennas are easily blown out of alignment by wind or even a light bump. A mount should be strong and well designed – preferably coming from a reputable mount vendor. It should be weighted down with enough blocks or sandbags to ensure that it stays fixed in place Poles sunk in cement should have a bolt that passes through the bottom of the pipe, extending beyond the edge of the pipe so that it will not turn or rotate within the concrete base. A pedestal mount that bolts into a cement base is a good solution for larger antennas. All poles should be perfectly vertical, or antenna alignment can be difficult.

Another problem we see from time to time is cheap antennas, often with poorly designed fine-tuning mechanisms. We recommend reliable name-brand products that meet industry standards. For example, we recommend Type 123 Class II antennas for 1.2m Ku band applications. Partners sometimes use Class I antennas which are not as robust and consequently can be difficult or impossible to properly align or cross-pol. Glass Fiber Reinforced Polyester antennas are best, as aluminum antennas will corrode. (Note that this is not applicable for Earth Station class diameter antennas, i.e. anything larger than 3.8 m.)

Recommended Annual Antenna Maintenance

We recommend annual inspection and maintenance of antennas. The maintenance program should include maintenance to the following items.

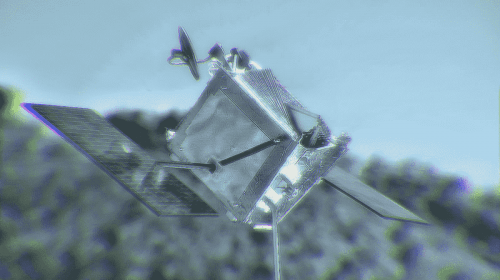

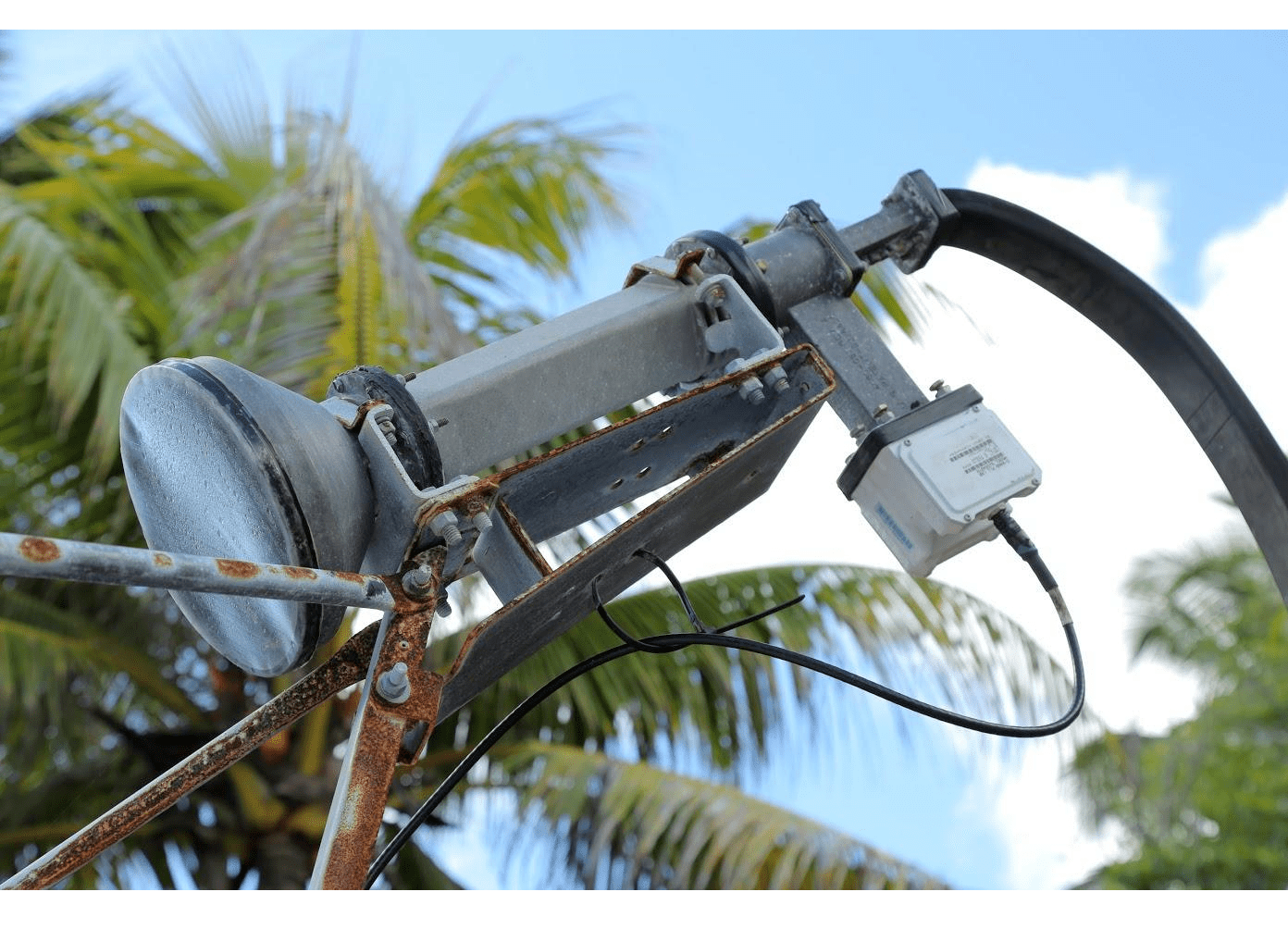

- 1. Inspect the total appearance of the equipment, including the antenna reflector, back-structure, BUC, LNB, and feedhorn.

2. Inspect the antenna mount hardware.

3. Inspect grounding (earthing) connections.

4. Inspect the power supply equipment and facilities.

5. Inspect the indoors IF equipment and terminal equipment (including modems, routers and M&C equipment, if installed.)

6. Inspect the rack enclosures.

7. Inspect the cables and connections.

8. Inspect components outdoors to insure they are adequately weatherproofed.

9. Evaluate the overall performance.

Maintain Cables

A visual inspection should include a check of nuts, bolts, rivets and other fasteners for corrosion. Tighten all loose bolts and replace badly corroded parts. The feedhorn should be closely inspected to make sure it’s not leaking water inside. Birds have been known to peck holes in the plastic covers which lets in water vapor which forms condensation reducing the SNR levels. If the BUC has a fan, confirm that it is operating properly and if not, repair immediately to prevent failure from overheating. Clean any filters that might be present and ensure chassis air passages are clear.

Inspection is a good time to confirm that there is a good ground, as this helps prevent damage from possible lightning strikes. Replace rusted or corroded hardware to prevent a build-up of resistance. Note that the “BusinessCom Grounding/Earthing Guidelines file is available to VARs on the portal in the Technical and Marketing Collateral Section.

New installations and annual inspections should include inspecting and verifying the cables. Check the weather sealing and replace any old cable ties. Inspect the coax cable run (IFL or inter-facility link) checking for sharp bends, or damage. Cables should preferably be supported with stainless steel cable hangers or clamps. If plastic tie wraps are used, make sure only black nylon ultraviolet resistant products are used. White and clear ties will become brittle and break with prolonged exposure to sunlight.

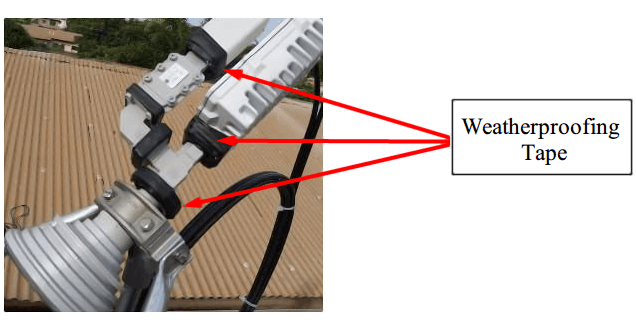

Weatherproofing

The application of sealing materials to antenna cable connections and feed assembly protects them from harsh weather conditions such as penetration by moisture, loosening of connections due to vibrations caused by heavy wind, and simple wear and tear. BusinessCom recommends the use of standard weather-proofing tapes, including butyl or plastic electrical tape. Tape should be applied to all outdoor cable connections (typically the coax connections to the BUC and LNB), and to all antenna feed assembly joints to help prevent corruption. BusinessCom recommends special publication SP50375-b by Andrew Corporation called “Weatherproofing Kit for Connectors and Antennas. This file is also available in the portal in the Technical and Marketing Collateral Section.

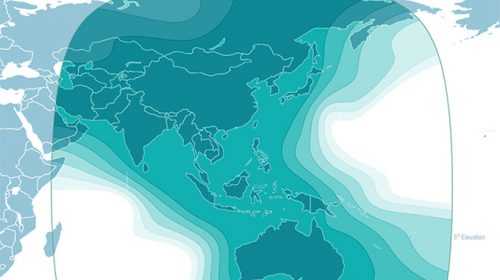

A properly weatherproofed feed assembly should look like this:

A properly assembled and maintained antenna can provide many years of service.

Please contact BusinessCom with any questions regarding ODU (outdoor unit) maintenance.